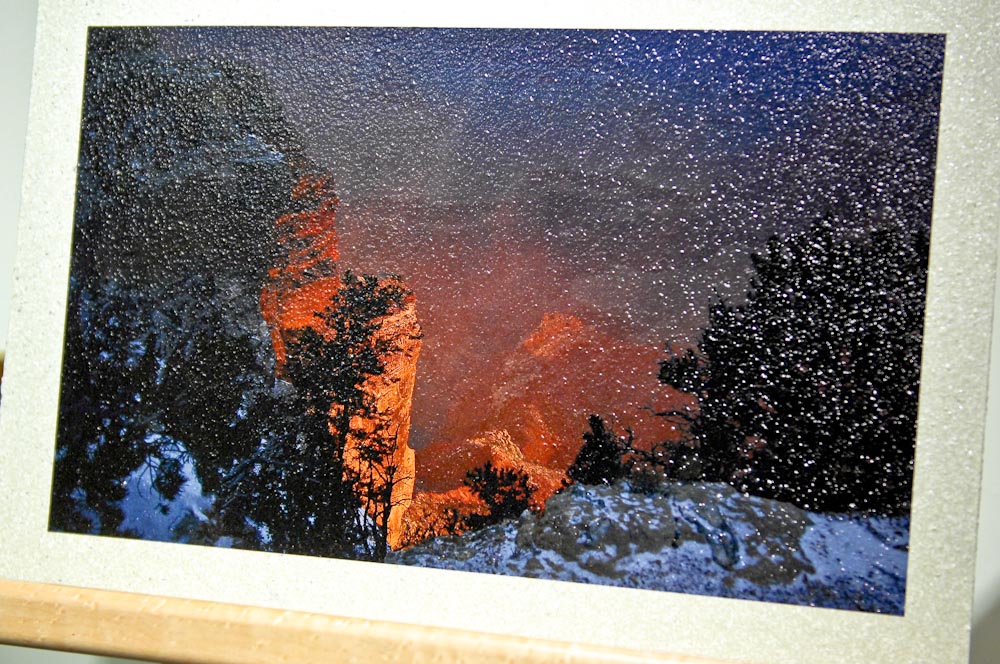

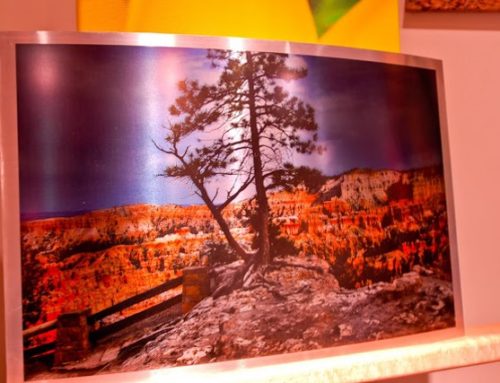

In 2011 we have added a new “One on One” alternative media printing workshop to our schedule. I would like to take a few minutes and show you one of the exciting projects we work on here. I have quite a few images from the south west United States and wanted something a little unusual to set them off. The textured stone finish available in several colors gives that unique desert southwest sandy look.

I am starting with .028 aluminum that I had custom cut from 10 foot sheets. A very cost effective way to print metal if you are doing more then just a few prints. After scuffing the metal with 320 grit sandpaper it was ready to receive the first coat of Rust-Oleum “Stone Textured” finish.

It normally takes overnight for proper drying between coats. I have several portable electric heaters set up to reduce the total drying time to a half day. For most of my metal prints 2 coats is sufficient. In this case I used 3 because of the rough texture.

Printed through the front feed of my Epson 3800. Came out pretty sharp looking and am anxious to try another.